By Bill Johns, Chief Scientist

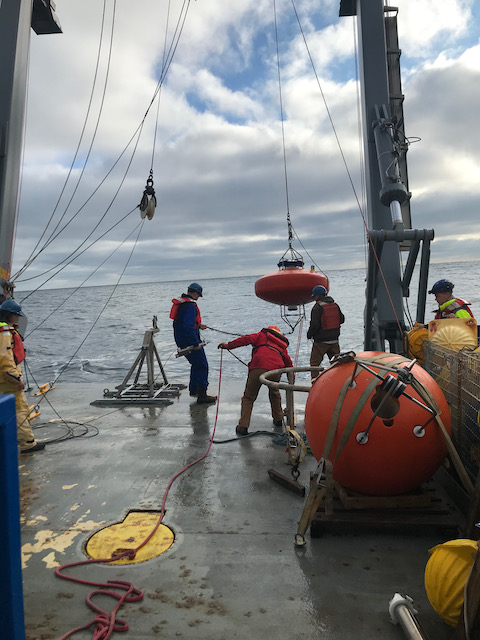

Our cruise is now about halfway through, and spirits are high as we steadily make progress on accomplishing our cruise objectives. Yesterday the final University of Miami mooring was deployed in the Iceland Basin, completing the turn-around operations on all of the seven moorings deployed along the eastern flank of the Reykjanes Ridge. We have now turned the mooring operations over to the NIOZ team, who at this moment are deploying their westernmost Irminger Sea mooring (see photo), and if all goes well will follow that with the deployment of their second (of five) moorings this afternoon.

It is a rather nice morning in the Irminger Sea, with relatively calm conditions and the sun even peeking through the clouds from time to time. Apart from a following swell that is occasionally putting some water on the aft deck, it is a fine day for mooring work, seriously challenging our usual mantra that “it is nicer in the Iceland Basin”. Our mooring operations there were mostly in overcast and often cold, drizzly conditions and so the weather today in the Irminger Sea is a pleasant surprise (however, not to be discussed further..). The only major glitch we have encountered so far is that one of the U. Miami moorings unexpectedly returned to the surface after its deployment, while communicating with the acoustic mooring releases to put them into “sleep mode” for the next two years until we come back again, and that mooring had to be recovered and redeployed again, basically costing us a day of ship time. This is one of the reasons, besides unpredictable weather, that we build a little extra time into our cruises for contingencies.

The U.S. and Dutch teams continue to work very well together, and this is particularly evident on deck during the mooring operations. During the first half of the cruise, when the U. Miami mooring work was taking place, the two lead technicians from NIOZ (Leon Wuis and Toon Koopman) ran the mooring winch for the U. Miami team, who were busy loading instruments and floats onto the mooring line as it was paid out. Now the lead U. Miami technicians (Eduardo Jardim and Cedric Guigand) are doing the same for the Dutch team as they recover and deploy their moorings. It is always interesting to see how different research groups approach their mooring operations, with somewhat different mooring designs and different methods of deployment. For example, the NIOZ team uses a “mooring table” (pictured in the photos) that has a built-in stopper system for changing mooring wires and attaching instruments, whereas for the U. Miami moorings this is all done at deck level using a traditional double line stopper system.

The mooring winch system we are using is a specially designed system called a LEBUS (aka “double barrel”) winch system (see photo) that is somewhat complicated but highly efficient for performing rapid mooring turnaround operations. It takes two people to run it with a third assisting, and with at four people on the aft deck making mooring connections, and several others bringing instruments in and out from the lab, it requires a large team and a carefully choreographed operation.

With the change-over in mooring operations, the night-time CTD watches have also changed at mid-cruise to free up personnel from the Dutch team for their mooring work. During the first half of the cruise, these watches were mostly manned by NIOZ scientists but now they are being mostly manned by the U. Miami team. Everyone is adapting to these changes well and pitching in wherever needed. It has been a great pleasure sailing with this entire team thus far, and – as we often say – “so far so good”, with our fingers crossed.